Manufacturing & Assembly

The Heart Of What We Do:

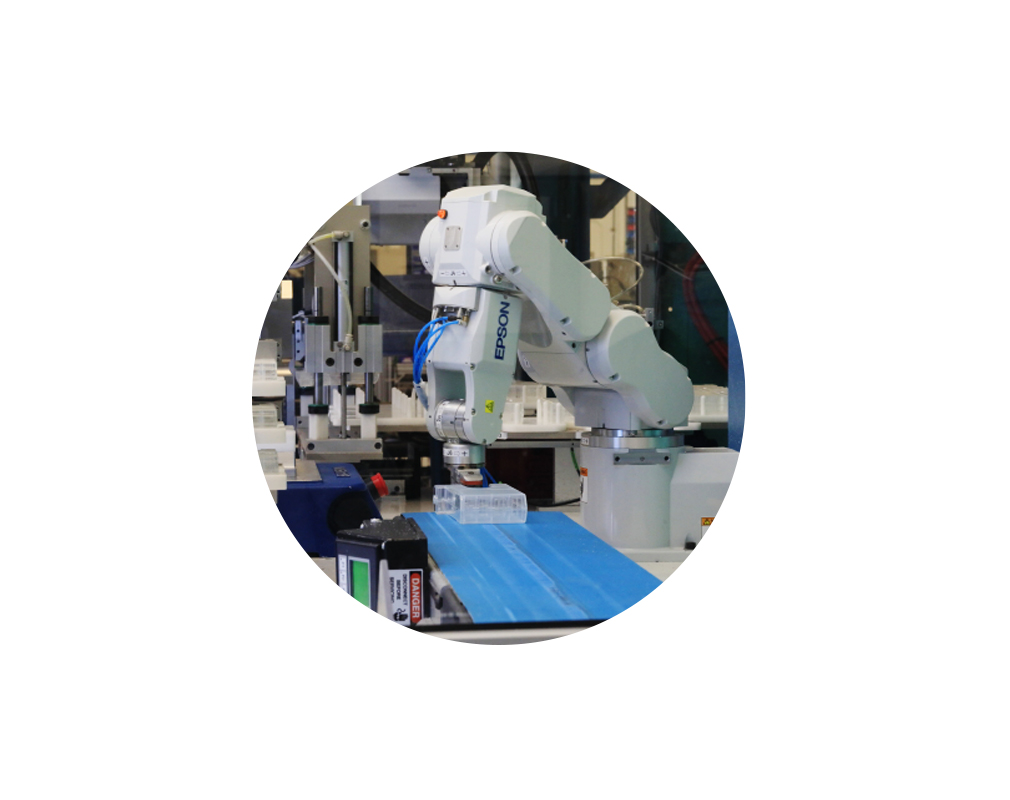

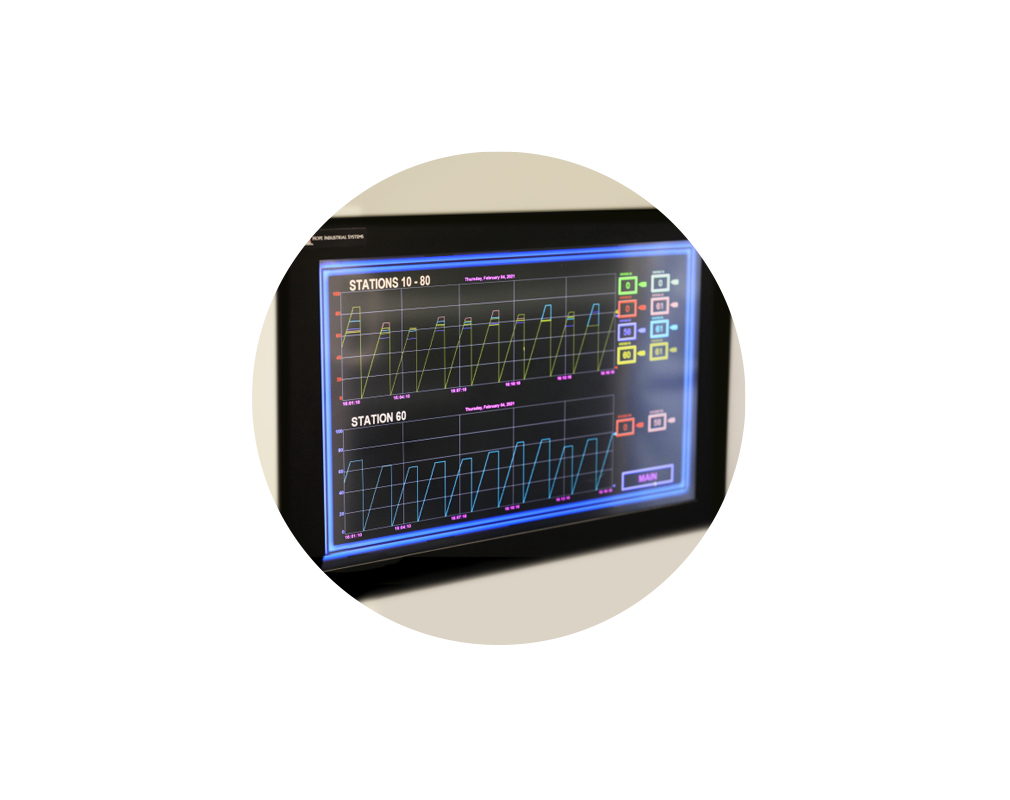

You need a reliable manufacturing partner – someone you can count on to deliver products that meet your needs each and every time. At Harmac, we use our extensive manufacturing knowledge to produce quality devices every day. Our long-term partnerships across our global facilities benefit our valued customers. Our automated solutions and vertically-integrated approach in managing multiple phases of the product life cycle provide scale and flexibility; quality and compliance are delivered regardless of volume.